Carmel Metal specializes in hot and cold forming, and implements a wide range of metal processing technologies and procedures to accommodate the diverse needs of our clients.

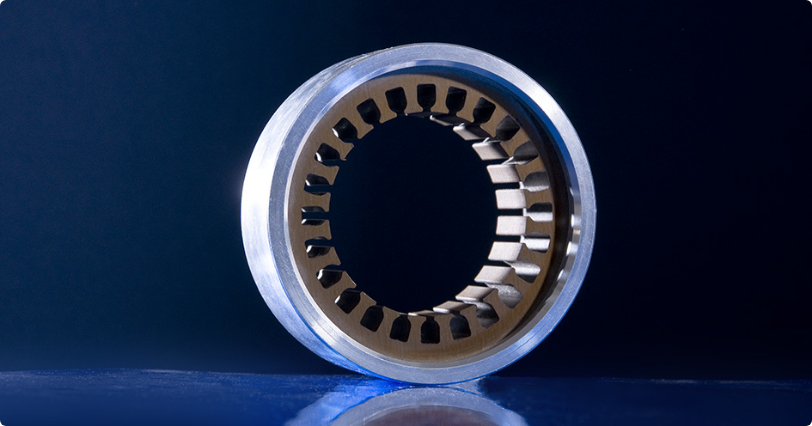

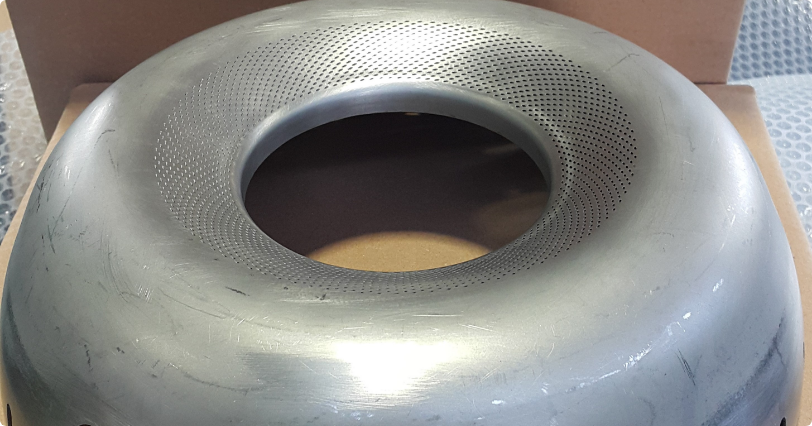

Machining is a versatile manufacturing process that is highly valued for its ability to create parts and components with tight tolerances and complex geometries. This method is often the preferred choice for creating intricate shapes and features that cannot be achieved through other manufacturing processes.

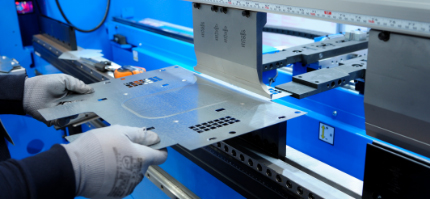

At Carmel Metal, we take machining seriously and invest in advanced technology and highly skilled professionals to ensure that our machining operations meet the highest standards of quality. We offer a comprehensive range of machining services, including cutting, drilling, milling, turning, and grinding, as well as advanced techniques like CNC, 3D laser processing, and computerized wire cut cutting (EDM). Our team of professionals is trained to operate diverse machines used in the process, and our factory is equipped with four and 5-axis machining centers and CNC lathing machines. Combined with our advanced automated environment and compliance with high international standards and manufacturing protocols like AS9100, we provide our clients with superior quality products that meet their specific requirements.

Machining is a crucial process in a wide range of industries, including aerospace, automotive, medical and more. From producing parts for airplanes to electronic components, the applications of machining are endless. At Carmel Metal, we strive to provide our clients with efficient, cost-effective, and high-quality machining solutions that meet their needs and exceed their expectations.