Carmel Metal specializes in hot and cold forming, and implements a wide range of metal processing technologies and procedures to accommodate the diverse needs of our clients.

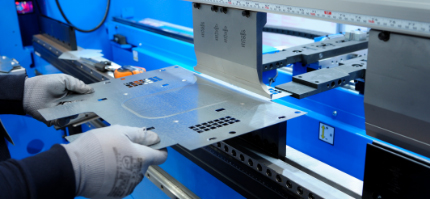

Cold forming is a popular manufacturing process that involves shaping metals through plastic deformation at or below room temperature. The process utilizes a range of techniques such as bending, drawing, rolling, impact extrusion, and cold forging to attain the desired shape of the material.

With decades of experience and expertise in deep drawing, stamping, and CNC spinning, Carmel Metal possesses the proficiency to perform cold forming on a wide range of metals from steels to elite alloys. We operate with a team of professionals that utilize 25 mechanical presses with a pressing capacity ranging from 22 to 400 tons. We also have 15 double-action hydraulic presses with a capacity of 4 to 500 tons, in addition to 5 feeders for large-scale serial fabrication.

Cold forming offers several advantages, including precise shaping of metals without the requirement of high temperatures, leading to cost and energy-efficient production. Our cold-formed components are known for their superior quality, excellent surface finish, and tolerances. As cold-formed products undergo deformation at below recrystallization temperature, they develop increased strength, hardness, as well as resistance to wear, corrosion, and fatigue.

At Carmel Metal, we deliver high-quality cold-formed metal parts and components to leading companies across multiple industries such as aerospace, defense, automotive, agriculture, and air conditioning.